May 6, 2024

ecomag-admin

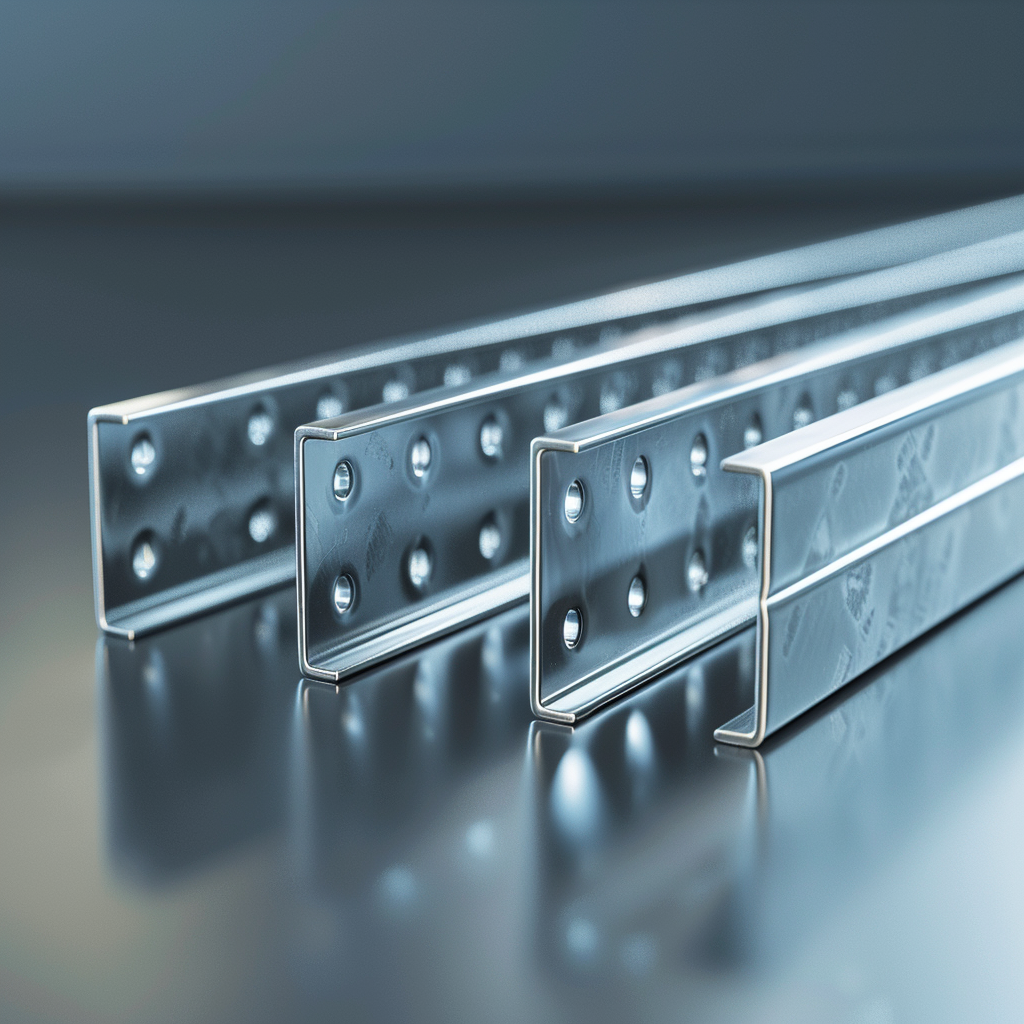

Cold-Formed Steel (CFS) Structures: Combining Strength with Sustainability

As the construction industry continues its pursuit of sustainable practices, innovative building materials that harmonize strength and environmental responsibility are becoming increasingly sought after. One such solution that has captured the attention of architects, engineers, and builders alike is cold-formed steel (CFS) structures. At Ecomag, we are at the forefront of promoting eco-friendly construction solutions, and CFS structures have emerged as a game-changer in this arena.

Unparalleled Strength and Durability

One of the most remarkable features of CFS structures is their exceptional strength-to-weight ratio. Despite their lightweight nature, these structures boast unparalleled durability and resilience, capable of withstanding significant loads and stresses. This inherent strength not only ensures the longevity of the building but also contributes to its overall safety, making CFS an ideal choice for projects where structural integrity is paramount.Sustainable Manufacturing and Recyclability

What sets CFS structures apart is their eco-friendly manufacturing process and inherent recyclability. Ecomag sources its CFS components from manufacturers who prioritize sustainable practices, minimizing waste and energy consumption during production. Furthermore, steel is one of the most recycled materials globally, with CFS structures being 100% recyclable at the end of their lifespan. This closed-loop cycle significantly reduces the demand for new raw materials, conserving natural resources and minimizing the environmental impact of construction projects.Design Flexibility and Versatility

CFS structures offer architects and designers unparalleled flexibility, allowing them to bring their most innovative and creative visions to life. With the ability to be formed into various shapes and profiles, CFS can be seamlessly integrated into a wide range of architectural styles, from sleek modern designs to traditional aesthetics. This versatility empowers architects to push the boundaries of design while adhering to sustainable principles.Energy Efficiency and Thermal Performance

In addition to their structural prowess, CFS structures contribute to the overall energy efficiency of buildings. Their precise manufacturing and tight connections create a highly insulated envelope, reducing air leakage and thermal bridging. This enhanced thermal performance translates into lower energy consumption for heating and cooling, further reducing the building’s carbon footprint and operating costs.Applications in Sustainable Construction

CFS structures have found widespread applications in sustainable construction projects, from residential homes to commercial and industrial buildings. Ecomag’s expertise lies in providing CFS solutions for a variety of applications, including:- Structural Framing: CFS studs, joists, and trusses form the backbone of energy-efficient and durable building structures.

- Facades and Cladding Systems: CFS components can be integrated into innovative facade designs, enhancing the building’s aesthetic appeal while contributing to its thermal performance.

- Modular and Prefabricated Construction: The lightweight and precise nature of CFS makes it an ideal choice for modular and prefabricated building systems, reducing construction waste and enabling off-site manufacturing.